Many variables can affect gasket sealing such as internal pressure, temperature, gasket design, and flange load. Sometimes it is necessary to dig a little deeper into the actual sealing picture when a difficult or critical sealing situation is encountered. In this article, we will explore a process we call “Fuji Testing”.

How Fuji Testing Works

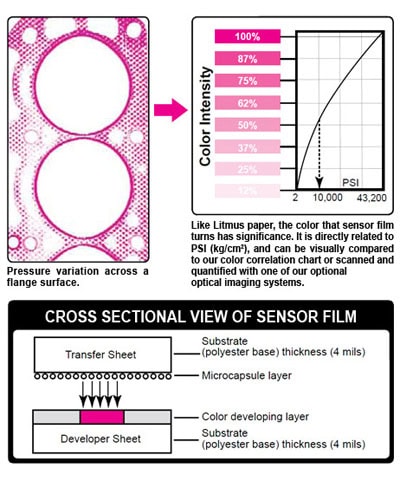

Fujifilm Prescale is a polyester based film that contains a layer of tiny microcapsules. The application of force upon the film causes the microcapsules to rupture, producing an instantaneous and permanent high resolution “topographical” image of pressure variation across the contact area. The use of this tactile sensor film is one method CGR Products uses to help customers see a “Static” picture of how the gasket is sealing in the current application.

We place the Fuji film between any two surfaces that touch, mate or impact. Apply pressure, remove it, and immediately the film reveals the pressure distribution profile that occurred between the two surfaces. Like litmus paper, the color intensity of the film is directly related to the amount of pressure applied to it. The greater the pressure, the more intense the color.

Analyzing the Fuji Data

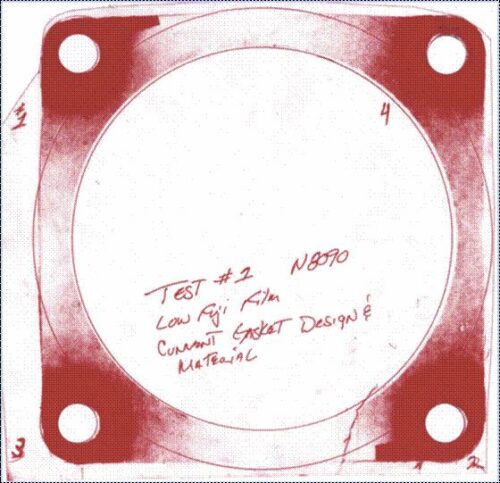

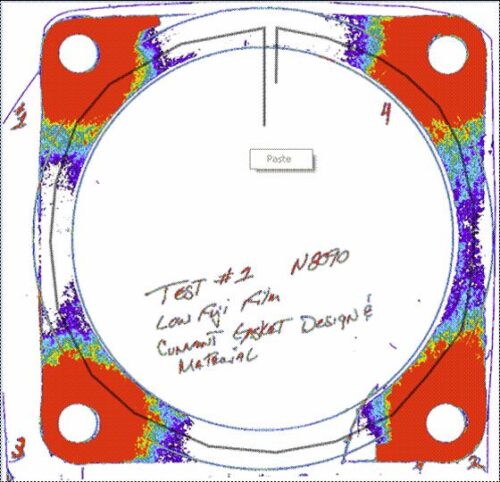

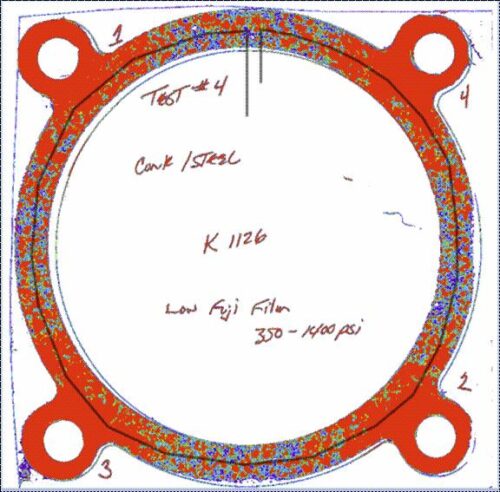

The principle way in which CGR Products uses Fuji film is to determine if the current gasket design is producing an acceptable seal to satisfy the customers’ requirements. In our example below, you are looking at a currently designed gasket where its highest pressure points are at the bolt holes. The bolt pressure points left a softer area in the middle of the flange.

Making Recommendations

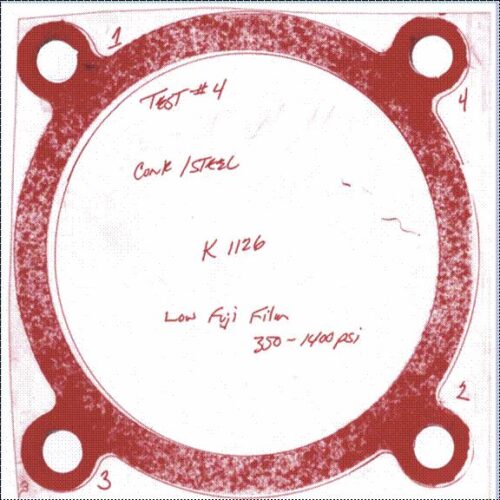

If it is determined that the sealing pressure revealed by the Fuji film is not acceptable, CGR Products can use the film data to determine a possible revised gasket design. These tests can also reveal that a material change is all that is needed to satisfy the sealing requirements. Using the same example, this is CGR Products proposed design and material change after Fuji analysis.

Learn More

To answer the question as to whether a Fuji analysis is right for you, Ask yourself if the potential warranty cost to your company is worth the time and effort. Let CGR Products help with your sealing issues so we can work together to solve potential warranty problems before they occur. Feel free to contact us with questions or dig deeper into our capabilities by clicking on our website.