CGR Products utilizes a variety of die cutting methods to produce a product that is precisely the shape and dimensions that are required. Our state-of-the-art methods can be used to cut almost any design out of soft, flexible non-metallic materials, as well as some harder and more rigid substrates. 1. Expertise and Quality Assurance CGR…

Unveiling the Top Reasons to Choose CGR Products for Your Sealing Solutions

CGR Products is renowned for its commitment to quality, expertise, and innovation in the realm of gaskets, seals, and custom fabricated sealing solutions. Choosing CGR Products as your gasket provider can be pivotal for various industries and applications. Here’s why sourcing gaskets from CGR is so crucial: Unparalleled Expertise CGR Products boasts extensive expertise in…

Component Foams Specifically Engineered for Automakers

Guest Author: Isabell Wright, Armacell . For most major car makers, all parts must be made from materials that are on their approved source list. It’s a competitive business and only the best suppliers with a proven track record of quality, new technology, on-time delivery and service will make the cut. Once a material has…

Speaker Gaskets for OEM Manufacturers

CGR Products works with many manufacturers die cutting speaker gaskets. Our gaskets are used in several markets including, marine speakers, automotive speakers, home speakers, and more. Our die cutting capabilities allow us to cut virtually any size and pattern for large volume applications. This article will describe a variety or materials and cutting methods used…

Heat Sealed 3M™ Thinsulate™

CGR Products has been supplying various types of 3M™ Thinsulate™ materials to the automotive market for more than 10 years. The 3M™ Thinsulate™ NVH material (noise, vibration, and harshness) is used in a variety of applications across many different industries and provides a wide variety of sound absorption and dampening properties. The Advantages of 3M™ Thinsulate™…

CGR Products is Helping To Fight COVID-19

Just a few months ago, we would have never imagined we would be fighting the pandemic that we’re now facing. CGR Products is currently classified as an “essential business”. We die cut critical engineered parts that go to other essential businesses. The amount of inquires we’ve received has been both overwhelming and a blessing, including companies that…

CGR Products News Release

CGR Products News Release: Growth Leads to a 30,000 sq ft Expansion and New High Volume Manufacturing Machinery Click Here to read the full news release.

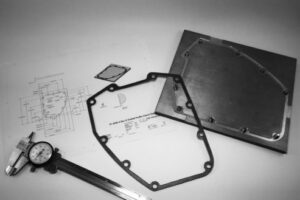

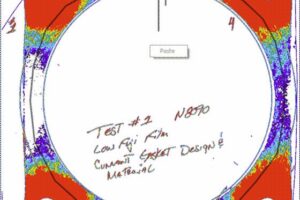

To Fuji or not to Fuji Test your Gaskets, That is the Question

Many variables can affect gasket sealing such as internal pressure, temperature, gasket design, and flange load. Sometimes it is necessary to dig a little deeper into the actual sealing picture when a difficult or critical sealing situation is encountered. In this article, we will explore a process we call “Fuji Testing”. How Fuji Testing Works…

Material of the Month: Felt

CGR Products stocks a large variety of materials for a wide range of applications. Flexible rubber sheeting, adhesive solutions, and fiber materials are just a few of our specialty options. Our Material of the Month series spotlights some of our favorite materials and their unique applications. This month, we’re discussing Felt. What is Felt? Felt…

Three Capabilities You Might Not Have Known About CGR Products

Here at CGR Products, we use a variety of cutting and fabricating capabilities on a daily basis. However, we do some fabricating that might seem “out of the norm” from our core manufacturing. In this article, we will highlight three things you might not have known about CGR Products capabilities. Metal Fabrication Capabilities All three…

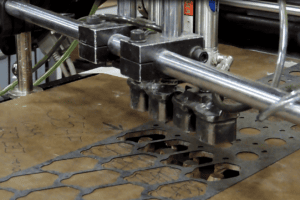

Rotary Die Cutting vs. Flatbed Die Cutting: Which Should You Use?

Die cutting is frequently used to fabricate unique shapes from rubber, plastic and foam materials. Before starting a die cutting project it is important to discuss all specific project requirements — including whether rotary die or flatbed die cutting is the best fit for the job. Each cutting method has its own distinct benefits based…

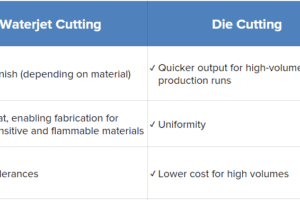

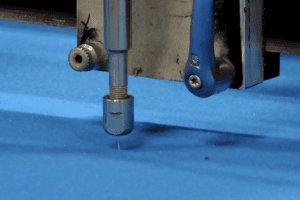

Die Cutting vs. Waterjet Cutting: Which One Should You Use for Your Project?

More cutting methods are available today than ever before. While friction sawing used to be the primary industrial material cutting option, there are now nearly a dozen viable choices. Not all cutting methods are created equal — which isn’t to say that one is categorically better than another, but rather that they all have their…

Cutting vs. Converting – What’s the Difference?

Don’t Get Tangled Up in Terminology The CGR team gets a lot of requests for cutting, converting, and fabricating. Fortunately for our customers, we do it all. As far as we’re concerned, these terms refer to the same process — the process of transforming a raw material into a precision component for your part. If…