CGR Products die cuts and converts a wide range of 3M VHB (Very High Bond) tapes into custom shapes and widths.

3M VHB Tapes are made with acrylic foam, providing outstanding strength and durability for highly demanding applications. The foam, which is viscoelastic in nature, utilizes energy-absorbing and stress-relaxing properties, which gives the tape its unique characteristics.

The completely closed-cell foam tapes are used to bond applications with dynamic forces in exterior and extreme conditions. The degree of bond achieved allows VHB to replace non-tape fastening methods such as mechanical fasteners, liquid adhesives, and other permanent fasteners.

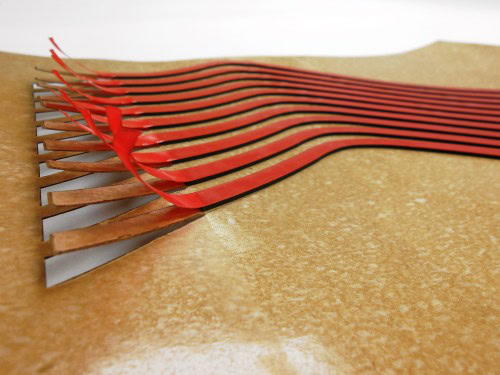

CGR Products is a 3M Preferred Converter, and utilizes a variety of cutting methods to ensure your product meets the shape and dimensions that you require with the utmost precision.

Better Design, More Flexibility, and Faster Turnaround

CGR’s precision die cutting capabilities enable VHB tapes to fit any shape, size, or profile while helping to minimize assembly time. The specialty bonding tape can also conform to the irregularities of all rigid substrates, even when there might be a slight mismatch while maintaining high internal strength.

Substantially shorter lead times are made possible by CGR’s complete in-house tool and die capabilities. We maintain an extensive inventory of the material, and our precision-cut services promise the highest performance for your product.

Strength and Durability

3M VHB Tapes’ all-acrylic construction delivers the following benefits:

- Ability to instantly bond with high holding strength for static/dynamic stress

- Viscoelastic properties to absorb shock for reliability against wind, vibration, and other stresses

- Resistance to extreme temperatures, UV light, moisture, and solvents

- Sealing properties against environmental conditions

- Prevention against bi-metallic corrosion

- Elimination of pull-through, dimpling, and weld distortion

In tests, the VHB yielded 92% retention of peel adhesion after the roll was aged for more than 5 years at 150°F. The initial tack and liner release properties were still excellent, proving that a roll of VHB tape can tolerate periodic, long-term exposure to elevated temperatures. Other tape durability tests have also been conducted that prove VHB tapes’ resistance to heat, humidity, and UV exposure.

Access the 3M Tape Resources Here

Performance Data and More

For more information about 3M VHB tape, access our resources with technical data, performance information and more.