Adhesive bonding is often required for projects in many applications and industries. With various types of bonds available to meet virtually any need, it’s important to know how to pinpoint the best option for your unique project. When discussing your application with a bonding products manufacturer, you will be presented with a series of questions…

CGR Products News Release

CGR Products News Release: Growth Leads to a 30,000 sq ft Expansion and New High Volume Manufacturing Machinery Click Here to read the full news release.

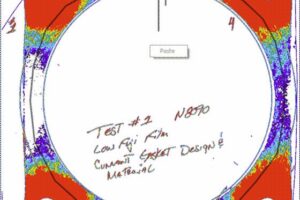

To Fuji or not to Fuji Test your Gaskets, That is the Question

Many variables can affect gasket sealing such as internal pressure, temperature, gasket design, and flange load. Sometimes it is necessary to dig a little deeper into the actual sealing picture when a difficult or critical sealing situation is encountered. In this article, we will explore a process we call “Fuji Testing”. How Fuji Testing Works…

New Year, New Videos! See What We’ve Been Doing at CGR

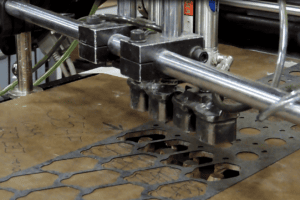

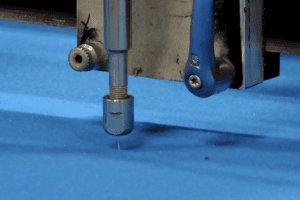

Water jet cutting, kiss cutting, custom die work — it was all on display at our Wisconsin Open House this past October. Our team was on-hand to help guests get acquainted with some of these state of the art machines, and took the opportunity to chat about some of our most successful recent projects. See…

CGR’s Open House: Facility Tour, New Equipment and More

CGR Products will be hosting an open house at our Wisconsin facility — offering tours of our ISO 9001:2008-certified facility and showcasing our new high-quality equipment. We want to show you our new state-of-the-art machinery used for our custom cutting and fabrication services. Our equipment is involved in a number of manufacturing processes, including die…

![[INFOGRAPHIC] Insider’s Tips To Packaging Issues [INFOGRAPHIC] Insider’s Tips To Packaging Issues](https://www.cgrproducts.com/wp-content/uploads/chrtopblog-300x200.png)

[INFOGRAPHIC] Insider’s Tips to Packaging Issues

An OEM’s guide to avoiding common packaging issues and eliminating unnecessary costs While generally overlooked during production, packaging solutions have a significant impact on your project’s overall costs. For OEMs requiring custom fabricated rubber, foam, and plastic products — such as gaskets, seals and tapes — there are a number of packaging solutions to not…

Rotary Die Cutting vs. Flatbed Die Cutting: Which Should You Use?

Die cutting is frequently used to fabricate unique shapes from rubber, plastic and foam materials. Before starting a die cutting project it is important to discuss all specific project requirements — including whether rotary die or flatbed die cutting is the best fit for the job. Each cutting method has its own distinct benefits based…

3 Reasons Manufacturing is Coming Back to America

Everyone is familiar with offshoring — the process of sending manufacturing projects across seas in an effort to save costs has been in practice since the 1960s. But now a new trend is emerging called reshoring. Also known as “inshoring” or “backshoring,” reshoring manufacturing is returning previously offshored manufacturing processes back to America. The original…

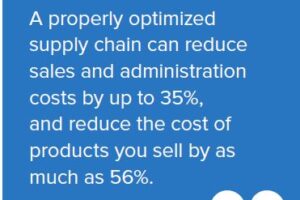

How Can OEMs Cut Costs and Optimize Their Supply Chain?

For original equipment manufacturers (OEMs), the stress of product design and manufacturing often overshadows the maintenance of a lean supply chain. Supply chain optimization is an initiative that always seems attractive, but it can be difficult to pinpoint just where to start. According to a recent TMG-IMG study, OEM supply chain management and optimization can…

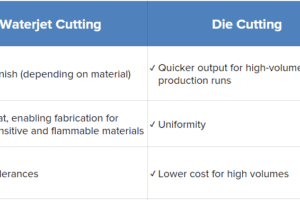

Die Cutting vs. Waterjet Cutting: Which One Should You Use for Your Project?

More cutting methods are available today than ever before. While friction sawing used to be the primary industrial material cutting option, there are now nearly a dozen viable choices. Not all cutting methods are created equal — which isn’t to say that one is categorically better than another, but rather that they all have their…

Material of the Month: EPDM Rubber

Highly Resistant and Versatile: A Solution for Everyday and Specialty Applications This blog post is the third installment of a new CGR Products content series called “Material of the Month.” The series spotlights some of the unique materials that CGR works with, as well as their common applications. Material selection can make all the difference…

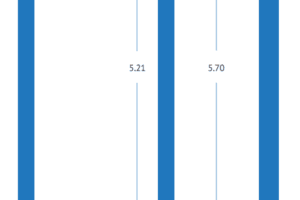

How Are Rubber Materials’ Tolerances Calculated?

Rubber parts are becoming more popular for manufacturing because of their ability to deliver flexibility in a wide range of temperatures and situations. Versatility is a top benefit, but only if materials are designed correctly. To prevent failures of critical parts and processes, the Rubber Manufacturers Association (RMA) has developed a table of tolerances that…

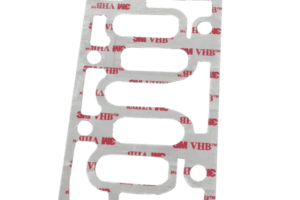

Material of the Month: Acrylic Foam Tapes

VHB Tapes can replace mechanical fasteners, liquid adhesives and more This blog is the first in a new CGR Products content series titled “Material of the Month.” The series will spotlight some of the unique materials and their applications that CGR works with. Our first material on the list is acrylic foam tape. What is…

Cutting vs. Converting – What’s the Difference?

Don’t Get Tangled Up in Terminology The CGR team gets a lot of requests for cutting, converting, and fabricating. Fortunately for our customers, we do it all. As far as we’re concerned, these terms refer to the same process — the process of transforming a raw material into a precision component for your part. If…

North Carolina Manufacturing Facts

For over 50 years we have provided North Carolina and the surrounding areas with cutting precision gaskets for MRO applications and OEM and MRO products for different markets. As we continue to be a key player in the manufacturing industry in North Carolina, we would like to note that manufacturing plays an important role in…