CGR Products stocks a large variety of materials for a wide range of applications. Flexible rubber sheeting, adhesive solutions, and fiber materials are just a few of our specialty options. Our Material of the Month series spotlights some of our favorite materials and their unique applications. This month, we’re discussing Felt. What is Felt? Felt…

Making a Decision

Over my career, I have had the opportunity to experience many decisions being made, a nice way to say I’m getting old. I have seen good ones and bad ones and I have made good ones and bad ones. Ultimately, over 90% of the value any person is to any organization is directly related to…

UL Materials | Closed Cell Sponge Rubber

Many users of sponge rubber products for sealing are unaware that UL guidelines dictate that when adhesive is applied to sponge rubber the chemistry has been changed. Essentially, this creates a new product which must pass specific tests to be added to a list of approved UL materials. To help solve this issue, CGR Products…

Material of the Month: Rogers Corporation PORON

Here at CGR, we stock a wide variety of specialty materials, from unique adhesive solutions and flexible rubbers to custom-engineered fibers. During our Material of the Month blog series, we’ve been showcasing some of our favorite, most popular materials, outlining their unique features and exploring common applications. This month, we’re highlighting our extremely versatile Rogers Corporation…

Working with Flexible Material? Avoid These Design Mistakes!

CGR Products was born in Greensboro, North Carolina, in 1963. We started out cutting precision gaskets for the textile industry, but we’ve come a long way — and seen a lot of mistakes — since then. Every day, our team cuts, slits, laminates, skives, and molds materials into precision components to serve clients in numerous…

Three Capabilities You Might Not Have Known About CGR Products

Here at CGR Products, we use a variety of cutting and fabricating capabilities on a daily basis. However, we do some fabricating that might seem “out of the norm” from our core manufacturing. In this article, we will highlight three things you might not have known about CGR Products capabilities. Metal Fabrication Capabilities All three…

Material of the Month: Closed Cell Sponge Rubber

Here at CGR, we stock a wide variety of specialty materials, from unique adhesive solutions and flexible rubbers to custom-engineered fibers. During our Material of the Month blog series, we’ve been showcasing some of our favorite, most popular materials, outlining their unique features and exploring common applications. This month, we’re highlighting our extremely versatile closed…

How Amorim Makes Cork Rubber

At Amorim Cork Composites — the world’s largest producer of cork and related materials — we’re committed to sustainability in everything we do: We recycle, reuse, and reinvent entirely natural and organic materials. Understanding the versatility and value of cork in numerous applications, we’re proud to supply companies worldwide with top-quality, reliable cork products. The…

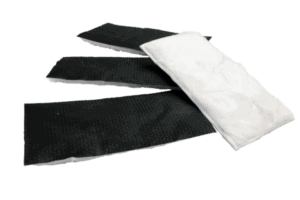

Using 3M Thinsulate to Manufacture Lighter, Quieter Cars

With mounting public concern over sustainability and increasingly strict fuel economy regulations, automakers worldwide are now focusing their efforts on lighter, more fuel-efficient vehicles. In fact, by 2025, automaker fleets in the United States and Europe will need to average more than 60 miles per gallon. To meet these new guidelines, automakers must implement incremental…

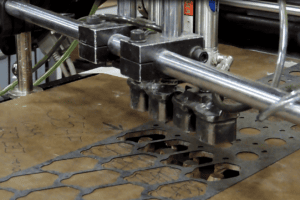

New Year, New Videos! See What We’ve Been Doing at CGR

Water jet cutting, kiss cutting, custom die work — it was all on display at our Wisconsin Open House this past October. Our team was on-hand to help guests get acquainted with some of these state of the art machines, and took the opportunity to chat about some of our most successful recent projects. See…

CGR’s Open House: Facility Tour, New Equipment and More

CGR Products will be hosting an open house at our Wisconsin facility — offering tours of our ISO 9001:2008-certified facility and showcasing our new high-quality equipment. We want to show you our new state-of-the-art machinery used for our custom cutting and fabrication services. Our equipment is involved in a number of manufacturing processes, including die…

Rotary Die Cutting vs. Flatbed Die Cutting: Which Should You Use?

Die cutting is frequently used to fabricate unique shapes from rubber, plastic and foam materials. Before starting a die cutting project it is important to discuss all specific project requirements, including whether rotary die or flatbed die cutting is the best fit for the job. Each cutting method has its own distinct benefits based on…

3 Reasons Manufacturing is Coming Back to America

Everyone is familiar with offshoring — the process of sending manufacturing projects across seas in an effort to save costs has been in practice since the 1960s. But now a new trend is emerging called reshoring. Also known as “inshoring” or “backshoring,” reshoring manufacturing is returning previously offshored manufacturing processes back to America. The original…

Protecting Adhesive Materials During Humid Summer Months

Summer’s heat and humidity can be especially damaging to adhesive materials. If not properly shielded , the siliconized release liner of your pressure-sensitive adhesives (PSA) will wrinkle and pucker in the heat — called cockling — resulting in overall production kinks and system failures. With the start of summer rapidly approaching, protection of your adhesive…

Material of the Month: Silicone Rubber

CGR Products stocks material choices of all kinds — flexible rubber sheeting, adhesive solutions, and fiber materials are just the beginning of our specialty options. Our Material of the Month series spotlights some of our favorite materials and their unique applications. This month, we’re discussing silicone rubber. What is Silicone Rubber? Silicone rubber is…