After CGR acquired an existing fabrication business in Waukesha, WI in 2012, one of our primary goals was to establish a partnership with the company’s existing customer base.

We had the opportunity to develop a strong relationship with one of the company’s clients while uncovering tolerance challenges in a number of their parts.

The Challenge:

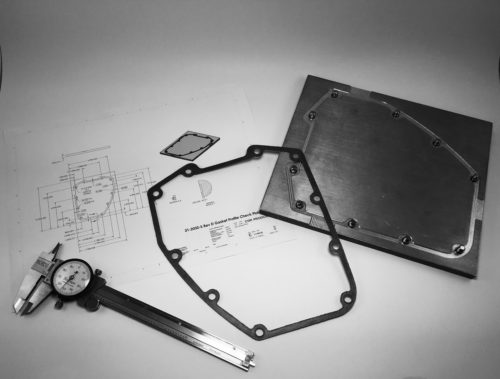

Using knife cutting, waterjet cutting, and acid-etched die cutting processes, we finish many products with extremely tight dimensional and thickness tolerances to meet our customers’ print specifications.

A few items, in particular, were being manufactured with an acid-etched die in order to maintain very tight dimensional tolerances per print. This method, however, prevented us from removing scrap produced by the die cut. As a result, we had to incorporate an additional step to the process to manually remove the slugs.

The Solution:

Thanks to knowledge acquired during our OEM Partner Program, we noticed that the customer was using a standard machined tolerance block on the drawings for parts made using flexible materials. These tolerances were impossible to meet with such flexible materials. CGR sent a tolerance declaration advising the customer that parts made from flexible materials are not capable of holding machined tolerances.

In an effort to clarify our tolerance declaration, CGR’s Account Manager and Quality Manager visited the customer’s facility in person. After some discussion, the customer was open to changing the required tolerances on their drawing to match RMA standards and adjusting the tolerances on other existing flexible materials that had machined tolerances.

Additionally, by purchasing a steel rule die with feed-through punches, our CGR team was able to completely eliminate the need for a secondary operation during the production process. This resulted in both a better understanding of tolerance capabilities for flexible materials and a more robust process capability for our customer.

Are you looking for a reliable company to serve as your industry partner? Reach out to our team today to see how we can work with you to enhance your production by aligning your processes with industry standards.

—

Watch Jenny Aguirre deliver a live presentation of this project’s details at our Open House.