Custom Beaded Gasketing: Your Solution to Gasket Sealability Problems

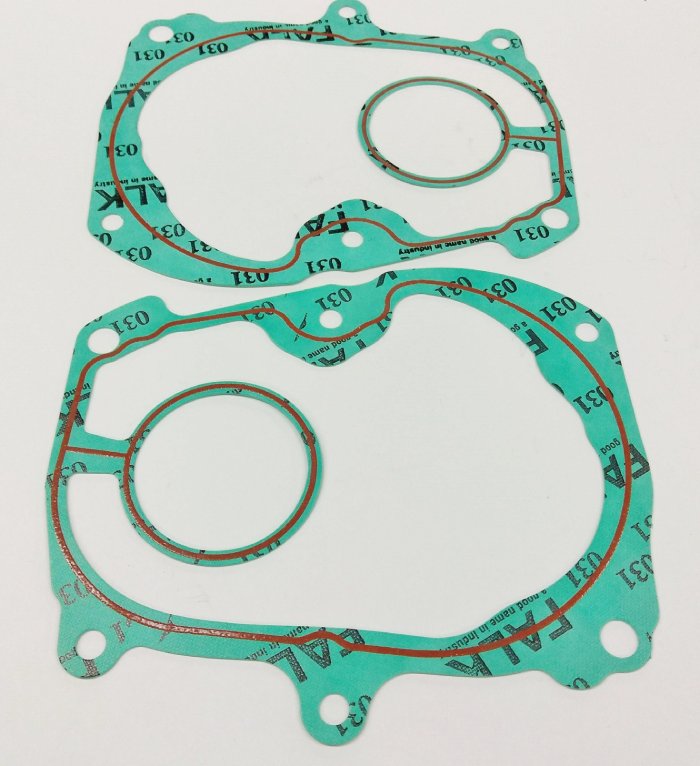

Gasket beading is an outstanding choice for improving sealability and can eliminate the need to redesign flanges or upgrade materials when resolving performance issues. Beaded gasket technology employs the application of a high-performance, resilient elastomer to the surface of a gasket. The bead improves the sealability of the gasket by concentrating available load on the areas of the gasket where the bead has been applied.

The applied bead effect is two-fold:

- The bead helps to seal flange irregularities. The elastomer conforms to gouges, scratches, and “as cast” surfaces to help provide an effective seal.

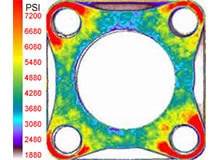

- The addition of the applied elastomer increases surface pressure and flange load exactly where your application needs it most. CGR Products can analyze the pressure distribution of your application with our flange analysis service.

The design and placement of the bead can greatly improve the sealing characteristics of the most problematic flanges without alteration to expensive machined or cast flanges.

Custom Capabilities Overview

Our gaskets can be designed to various thicknesses based on the sealing pressure required. The gasket material can be made from construction sheet, metal, or dual elastomer materials. We use various gasket fabrication processes including die cutting, kiss cutting, laminating, milling, molding, saw cutting, slitting, and turning to create beaded gaskets with a width of up to .125″ and a height of 0.001″ – 0.010″ using extremely tight tolerances.

Our gaskets are manufactured with precision so that our customers only receive quality workmanship for their assembly. This includes intensive inspection processes in place to ensure gaskets perform to optimal standards.

We use a number of inspection devices to ensure quality control: flange analysis, caliper measurement, coordinate measurement, final inspection, first article inspection, in-process inspection, micrometers, pin gauges, and Virtek LQC scanners. We can also perform a number of tests to understand pressure distribution and leak paths.

We can offer beaded gaskets in various production quantities from low to high volume runs with a standard 1 week lead time for typical materials. Non-standard materials may take more time as production is ultimately dependent on the material being used. Regardless, our beaded gaskets are backed by additional services that help provide value to our customers. This may involve bar code labeling, product certification, packaging, stocking programs, engraving or printing on parts, reverse engineering services, slitting, stripping, and waterjet cutting. We also offer a wide range of materials for custom die cut gaskets and seals which include 3M products, acrylics, EVA, polyurethanes, PTFE, rubber, Mylar, and much more.

With numerous industry standard qualifications, we ensure our beaded gaskets are the best in the industry. Serving multiple industries from appliances to small tractor manufacturing, we pride ourselves on innovation, customer service, and innovative performance in our product designs.