At CGR Products, we laminate many different materials on a daily basis. We can laminate materials up to 84″ wide and as thin as .062″. Materials can range from closed cell foam to heavy fabrics. In this series, we will look at some common ways CGR Products offers laminating services.

Heat Platen Laminating

This type lamination involves a process where the adhesive roll rides over a heated platen. Heat is used to soften the adhesive which is typically called “Flow”. The heat of the platen is computer controlled and is critical to the speed of the process. The material being laminated is pulled through the machine via driven rollers and the adhesive is applied to the bottom side of the substrate. The bond of adhesive to the substrate is performed at the nip roller. Once bonded the materials can be rewound and supplied on a core.

Watch our video below of closed cell foam being laminated with 3M9495 double coated adhesive.

Infrared Laminating

Infrared laminating is similar to heat platen laminating other than the heat source. This process uses Infrared heat to help the adhesive flow before it is applied to the material. One benefit of infrared is the heat can be micro adjusted while in process which allows the operator to quickly find the optimum temperature to create the best bond. The infrared process is instant so the heat can be started and stopped within seconds saving valuable time and material.

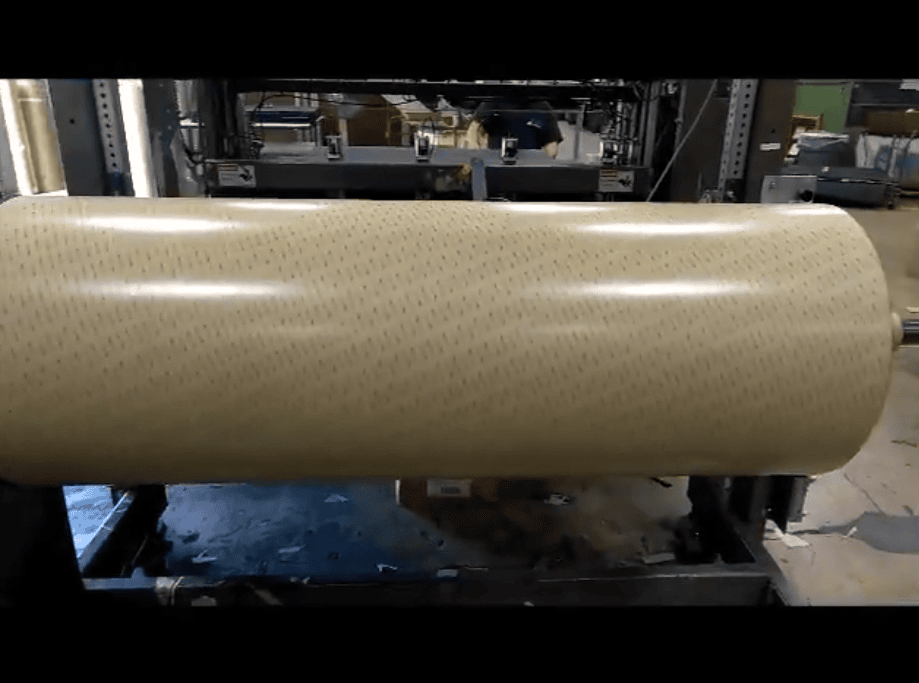

Hot Roll Laminating

Hot Roll lamination involves applying adhesive over a heated drum. The heated drum helps the adhesive flow just before being applied to the substrate. CGR Products hot roll laminator will handle materials up to 84″ wide. Our hot roll laminator is well suited for materials such as carpet and textiles. A common use for this machine is the process of glue web lamination. This process allows customers to reactivate the adhesive with heat when parts are ready to be installed.

Rotary Laminating

For high volume die cutting applications, we utilize Rotary lamination. We commonly laminate materials up to 16″ wide such as 3M VHB, Copper foils, and Mylar. Depending on the complexity of the part, we can usually laminate and cut the part in one pass. This helps to reduce cost and increase responsiveness to your customer.

Learn More

To learn more about our lamination capabilities, visit our laminating services page. Feel free to click around our website or visit our Sample Gallery to view a portfolio encompassing many of the industries we serve.