With mounting public concern over sustainability and increasingly strict fuel economy regulations, automakers worldwide are now focusing their efforts on lighter, more fuel-efficient vehicles. In fact, by 2025, automaker fleets in the United States and Europe will need to average more than 60 miles per gallon.

To meet these new guidelines, automakers must implement incremental improvements to reduce vehicle weight and improve efficiency. In this changing landscape, it’s imperative for automotive manufacturers to make use of lightweight, reliable materials.

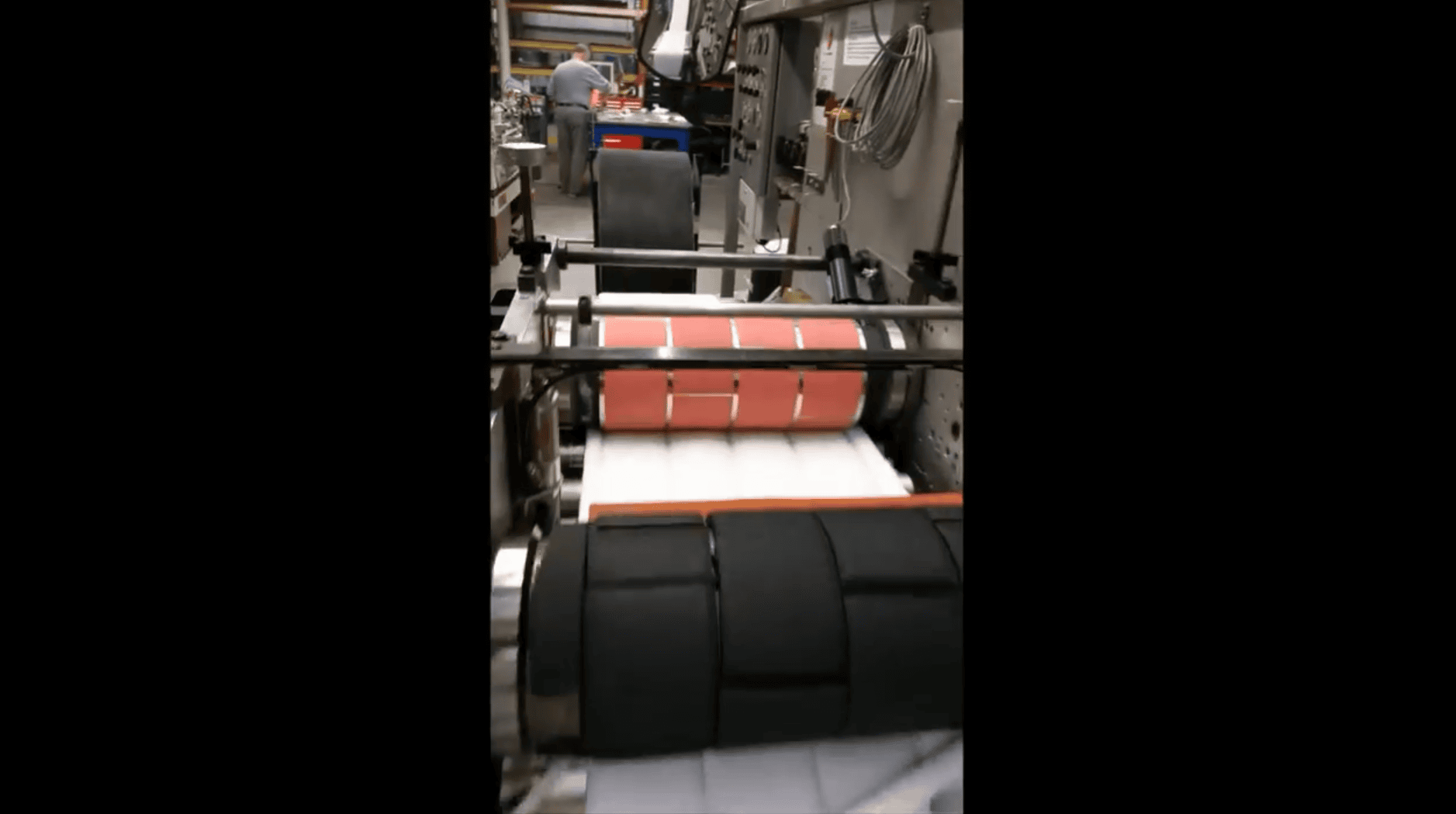

At CGR Products, we’re proud to be an approved converter for 3M’s innovative Thinsulate material — an ideal option for acoustic automotive applications.

The Advantages of 3M Thinsulate in Automotive Applications

3M Thinsulate Acoustic Absorption Material provides a reliable acoustic solution for various automotive applications. Incorporating only a few square centimeters of the material into components during fabrication greatly improves sound insulation and allows for greater efficiency. The benefits of 3M Thinsulate for automotive applications include:

- Quieter cars — Providing excellent acoustic absorption, especially for middle- to high-frequency ranges, 3M Thinsulate allows for overall quieter vehicle operation.

- Lighter cars — Made of lightweight polyester and polypropylene non-woven fibers, 3M Thinsulate can be used to fabricate lightweight automotive components without sacrificing quality.

- Easy bonding — This versatile material can be easily attached using ultrasonic welding, double-sided tape, or mechanical clips.

- Resistance to moisture and mildew — Absorbing minimal moisture, 3M Thinsulate is water repellent and mold resistant, eliminating the risk of odor and obviating the need for additional waterproof layers.

Automotive Applications

Automotive manufacturers can use 3M Thinsulate in the fabrication of a wide range of car parts, including:

- Doors

- Interior panels

- Seat backs

- Luggage compartments

- Headliners

- HVAC equipment

- Engine undercovers

- Leaf cowls

3M provides a variety of Thinsulate insulation materials to meet the unique needs of these specific applications. The 3M Thinsulate HT Series, for instance, is designed to withstand high-temperature environments, such as engine compartments, while the SM Series easily compresses for use in tight quarters, such as the vehicle cabin and luggage compartment.

Learn More

With over 140,000 square feet of manufacturing and warehouse space and over 100 top-quality machines, CGR serves a diverse range of clients, including those in the automotive industry. To learn more about our capabilities within this field, download our automotive application guide, or visit our Sample Gallery to view a portfolio encompassing all the industries we serve.