Eliminating Mirror Vibration in Heavy-Duty Vehicles: A CGR Products and Rogers Case Study.

Squeaks, rattles, and vibration are the kind of issues that keep engineers up at night, especially when they appear late in a vehicle program. That’s exactly what happened to a heavy-duty truck OEM during early road testing of a new cab design.

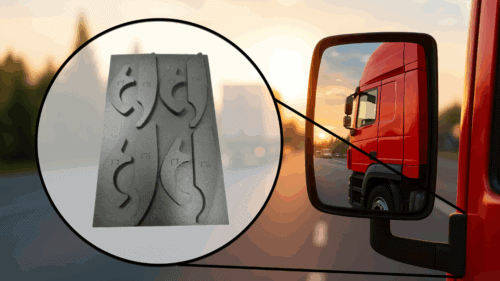

The side mirrors, mounted on injection-molded brackets, began shaking noticeably at idle and vibrating more severely at highway speeds. The issue wasn’t with the bracket design; it was the material used in the mounting interface that failed to dampen vibration effectively.

With production tooling already in place, the team needed a fast, reliable fix that didn’t involve redesigning the bracket system.

Customer Problem

The OEM’s side mirrors were showing excessive vibration under normal operating conditions. The concern wasn’t just cosmetic, it impacted driver confidence and posed a potential safety risk.

The challenge was to stabilize the mirrors without making changes to the bracket design, which had already been tooled for production.

Design Requirements

To be successful, the solution needed to:

- Dampen vibration and absorb shock without compromising structure

- Fit within tight dimensional constraints inside the mirror housing

- Deliver consistent, repeatable compression

- Resist compression set, temperature extremes, and long-term wear

- Support fast, error-free installation on a high-volume assembly line

The Solution

Rogers Corporation partnered with CGR Products, a trusted Rogers Preferred Converter, to develop a custom solution using PORON® 4701-50 polyurethane, a firm-grade material known for its excellent dimensional stability and vibration damping properties. The foam fit seamlessly into the mirror assembly and eliminated the vibration issue by providing consistent, reliable support with no additional design changes.

What made this solution successful was more than just the material. Rogers brought deep expertise in high-performance polyurethane foam, while CGR provided the converting experience needed to prototype multiple configurations, refine the design, and deliver fully kitted and labeled parts ready for the assembly line.

The Material: PORON Polyurethane

PORON® 4701-50 (Firm) was specified for its ability to meet the strict demands of this automotive application. This material offers a reliable balance of firmness, energy absorption, and durability, making it ideal for gasketing, cushioning, and vibration management in dynamic environments.

To aid in assembly, CGR Products laminated an adhesive to the back side of the PORON. This made for an easy peel-and-stick application for the manufacturer.

Advantages include:

✔ Consistent vibration damping from a predictable force-deflection response

✔ Excellent compression set resistance to maintain sealing force over time

✔ Reliable energy absorption that holds up under repeated compression cycles

✔ Tight thickness tolerances for uniform fit across mirror assemblies

✔ Conformability to uneven or imperfect mounting surfaces

✔ Thermal and environmental stability in harsh automotive conditions

The Process

CGR’s engineering and converting team worked closely with the OEM to develop a ready-to-implement part:

- Analyzed vibration issues and the bracket geometry to determine optimal placement

- Prototyped 6–10 part iterations with varying thicknesses and firmness levels

- Tested and refined performance through real-world vibration simulations

- Waterjet labeled each part for clear identification during assembly

- Delivered as a kit, streamlining installation at the manufacturing plant

CGR was able to match high-performance material with precision lamination and waterjet converting, delivering speed, reliability, and accuracy every step of the way.

The Result & Key Takeaway

The mirror vibration was fully resolved, and the truck cab program moved forward on schedule without any design changes or tooling rework. The success came down to smart material selection and a focused, collaborative engineering effort.

For engineers working through similar vibration, sealing, or tolerance challenges, this case shows what’s possible when high-performance materials and expert converting come together to solve a real-world design problem, quickly and effectively

Partnering with CGR

Our staff are experts at finding creative solutions to manufacturing problems. At CGR, custom solutions are truly our specialty.

Do you have a problem that requires an innovative solution? Contact us today to discuss how we can help.